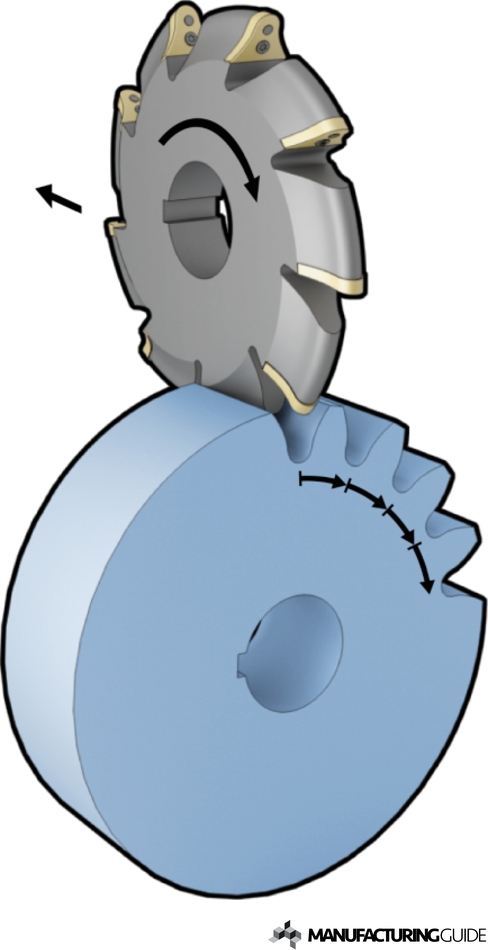

So, gear designs that require high precision - even double helix gears - can be fabricated with this method. The Sunderland method is excellent at creating teeth of uniform shape, and all gears that are cut by the same cutter will, in theory, gear correctly with one another. The teeth profiles follow a geometry that consists of an involute of a circle - basically a spiraling curve traced by the end of an imaginary string unwinding itself from that stationary circle - or if you trace the point of contact from one tooth to another as shown on Figure 1. It uses specific relative motion between the workpiece and the cutter during machining to produce teeth profiles and is similar to a rack and pinion as depicted in Figure 2. The process is also known as the Sunderland method, which consists of a rack cutter that has rake and clearance angles to create the teeth profile on a gear blank. Rack type cutters are used in one of the primary methods of gear generation. Gear form cutting involves tools that are used to create the gear profile (gear milling, shaping, slotting, planing, and EDM).Gear forming processes create gears without using cutting tools (rolling, casting, powder metallurgy, 3D printing).Gear generation methods use cutting tools in the shape of the desired gear profile to create the gear (rack cutters, gear shaping, and gear hobbing).As new technologies are developed, there may be new gear machining methods added to the list, but the big three are still the most common ways to make a gear: Historically, gear fabrication methods fall into three main categories: generation, forming, and form cutting.

0 kommentar(er)

0 kommentar(er)